Nanotechnology, the science of manipulating matter at the atomic and molecular scale, has ushered in a new era of innovation across various industries.

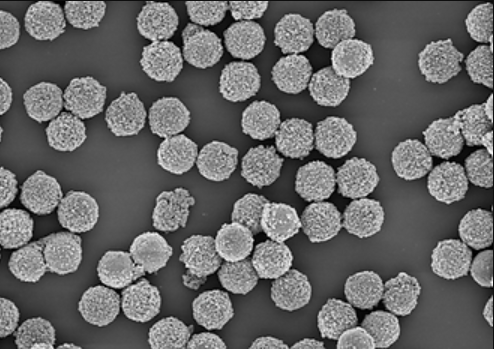

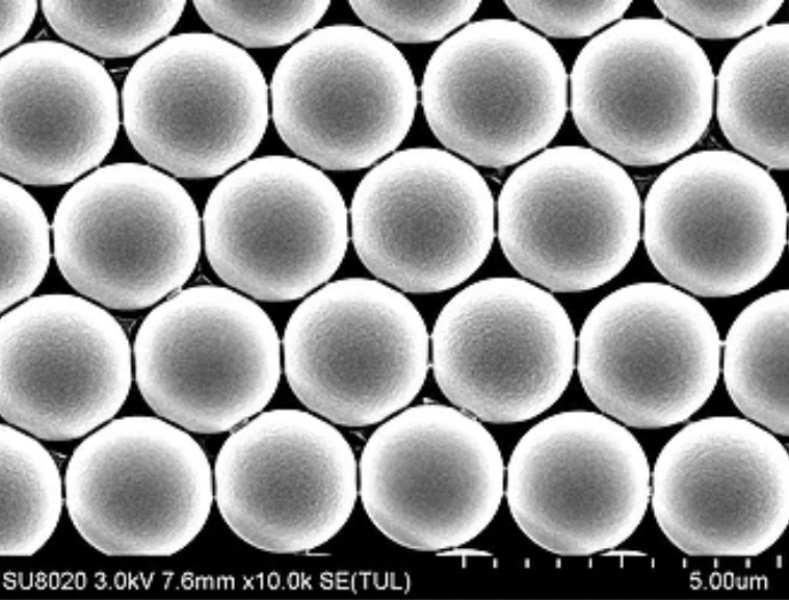

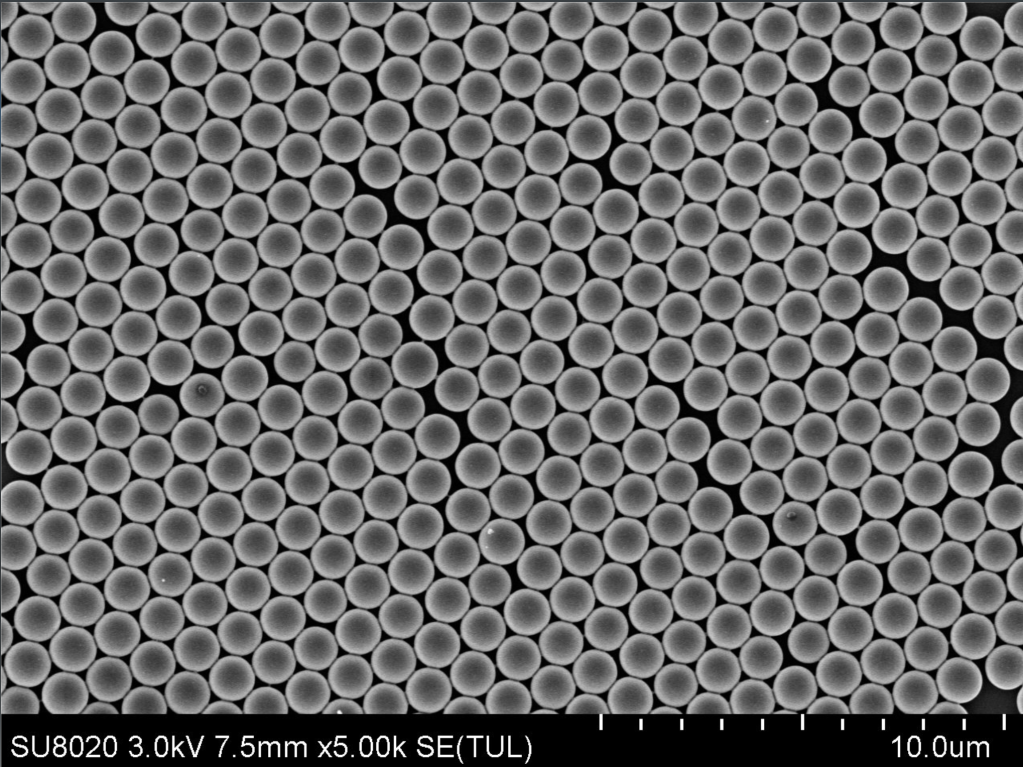

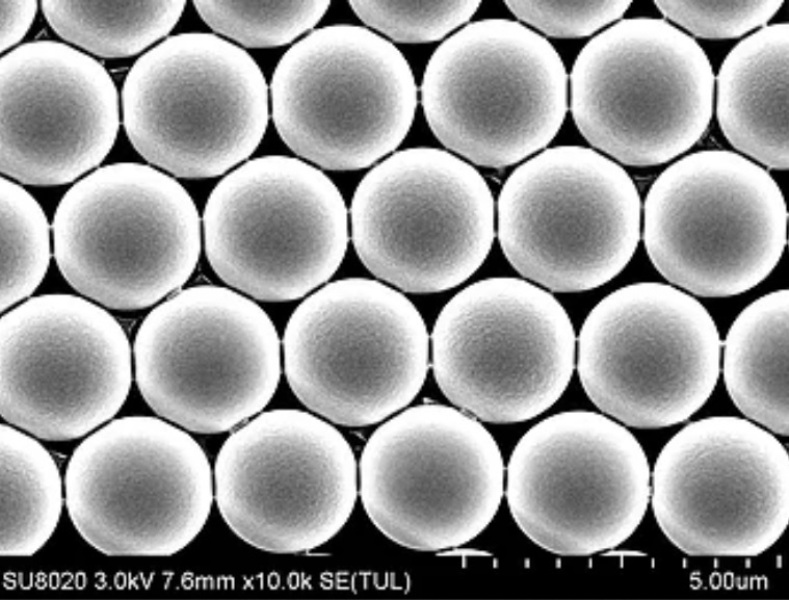

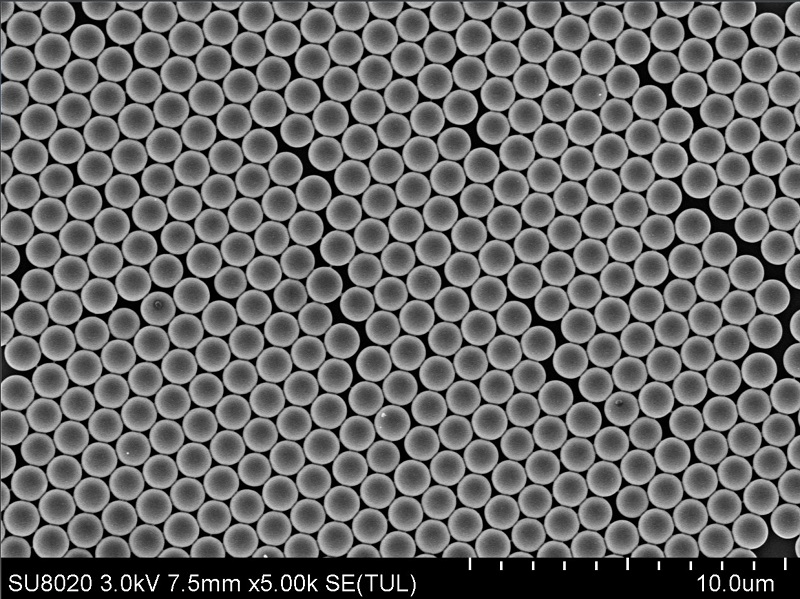

The Silica nanoparticles, derived from silicon dioxide, possess unique properties owing to their nanoscale dimensions. Their high surface area to volume ratio, tunable porosity, and biocompatibility makes them invaluable in a plethora of applications.

Biomedical applications

In the world of medicine, the nanoparticles have emerged as promising candidates for drug delivery, imaging, and therapeutics. Their ability to encapsulate drugs within their porous structure facilitates targeted delivery, reducing side effects and enhancing efficacy. Moreover, functionalization of this with targeting ligands enables precise localization within the body, revolutionizing treatments for cancer, infections, and other diseases.

Catalysis and sensing

Silica nanoparticles serve as catalyst supports in heterogeneous catalysis, accelerating chemical reactions while minimizing waste. Additionally, their optical properties make them ideal candidates for sensing applications, including environmental monitoring, food safety, and diagnostics. By modifying the surface chemistry of silica nanoparticles, scientists can tailor their properties to detect specific analytes with exceptional sensitivity and selectivity.

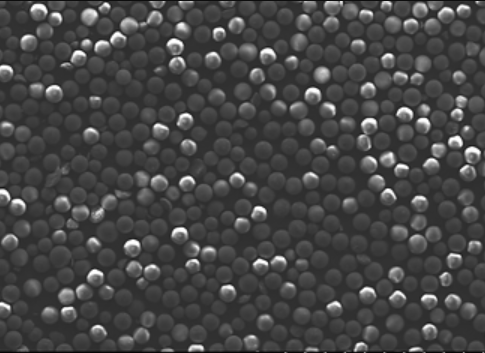

Introducing magnetic silica nanoparticles

Combining the advantages of Magnetic Silica Nanoparticles with magnetic functionality yields a hybrid material with enhanced capabilities. By incorporating magnetic elements such as iron oxide or cobalt ferrite, researchers have unlocked new opportunities across various domains.

Biomedical imaging and therapy

The magnetic properties of these nanoparticles enable magnetic resonance imaging (MRI), providing detailed anatomical and functional information for diagnostics. Moreover, in the field of therapeutics, magnetic silica nanoparticles hold promise for targeted drug delivery and hyperthermia-based cancer treatments. By applying an external magnetic field, these particles can be guided to specific sites within the body, enhancing treatment efficacy while minimizing systemic toxicity.

Environmental remediation

Functionalized with adsorbent materials, such as activated carbon or polymers, these nanoparticles can efficiently capture contaminants from water and soil. The magnetic component facilitates easy separation and recovery post-treatment, mitigating secondary pollution and reducing the environmental footprint.

Conclusion Silica nanoparticles and Magnetic Silica Nanoparticles represent a convergence of nanotechnology and materials science, offering unprecedented opportunities across diverse industries. From revolutionizing healthcare to safeguarding the environment, their multifaceted applications continue to inspire researchers and innovators worldwide.