If you want to store samples or solutions of any kind, UV quartz cuvettes are necessary. The ideal UV quartz cell with PTFE screw caps and septa would be the equipment or product that every person needs to get amazing benefits and results. For anyone looking for amazing results and effects in scientific research, UV quartz cuvettes are a must.

Are you looking forward to discovering great UV Fused Quartz Cuvettes? If yes. On this website everyone can learn more about the benefits of UV quartz cells, which have the potential to become the ideal resource. Quartz cuvettes are a great help for anyone who is constantly looking for the best experiments, results, or effects.

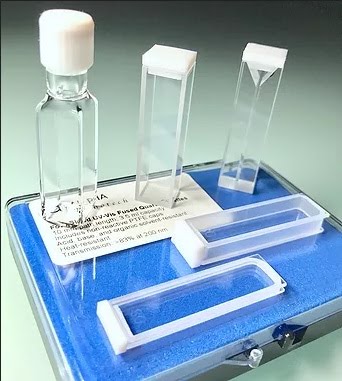

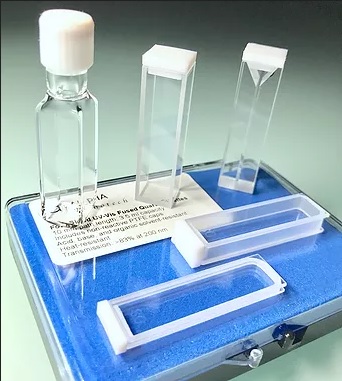

UV quartz cells are essential for all experiments in science and medicine. 10 mm quartz cuvettes with stoppers are the answer to all desires for precise and error-free test results. Do you need some of the best UV quartz cuvettes? If yes. With incredible UV fused quartz cuvettes and UV quartz cells with PTFE septa and screw caps, Alpha Nanotech is a world-class platform. Any scientific experiment or research must have access to these products. The robustness of UV shot quartz or quartz cells is undeniable. Large quartz cuvettes last much longer than typical glass or plastic cuvettes. Due to the perception that UV quartz cuvettes are expensive, many people are hesitant to purchase them. UV quartz cuvettes are inexpensive and not expensive. By connecting with the Alpha Nanotech platform, you can purchase the products at a low cost. Forward! And claim the impeccable and incredible benefits of dry oxide diced silicon wafers and quartz cuvettes with PTFE lids.

What is UV vs. Cuvette?

The most popular UV Fused Quartz Cuvettes are cuvettes with rectangular test tubes made of quartz material for use in UV-Vis spectroscopy measurement systems. Like conventional test tubes, they are used to store aqueous solutions. Regular test tubes are useful in chemical reactions. UV-Vis cuvettes, on the other hand, are used in UV-Vis spectrophotometers or fluoro meters to determine the transmission or absorption of radiation at a specific wavelength in the UV and visible range of 190, – 2,500 nm.